Introduction:

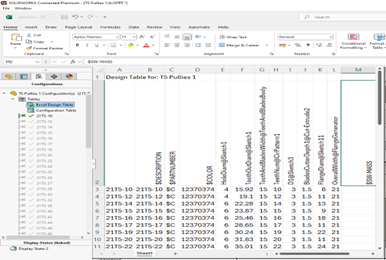

In SOLIDWORKS, parametric design is enhanced through the use of Design Tables, which allow engineers to manage multiple configurations of a part using an Excel-based interface. By integrating the $SW-MASS property and Custom property users can dynamically calculate and track the mass of each configuration. However, without proper setup, these properties may not update correctly across different configurations or views. This guide explains how to configure Design Tables and link $SW-MASS to ensure accurate and automated updates in your models.

Understanding the Problem

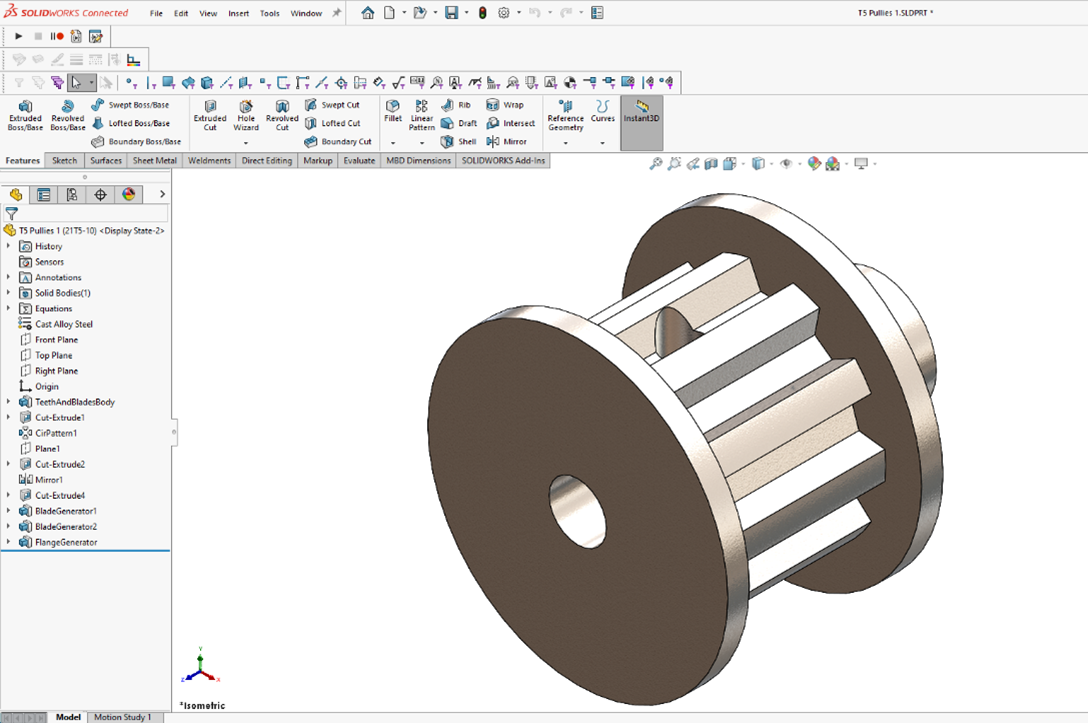

When working with configurable parts like pulleys, engineers often need to adjust parameters (e.g., number of teeth, blades, and width) and track mass across multiple configurations. By default, SOLIDWORKS may not automatically reflect these changes or the $SW-MASS property unless explicitly linked. This can lead to manual updates, inconsistencies, and inefficiencies, especially in complex designs with numerous configurations.

Real-World Scenario

Imagine designing a series of pulleys (e.g., TS Pulleys 1. SLDPRT) where each configuration varies by the number of teeth and blades, with mass being a critical factor for performance analysis. Manually updating the mass and dimensions for each configuration is time-consuming and error prone. The ideal solution is to automate this process using a Design Table linked to $SW-MASS.

Figure 1: 3D Pulley Model

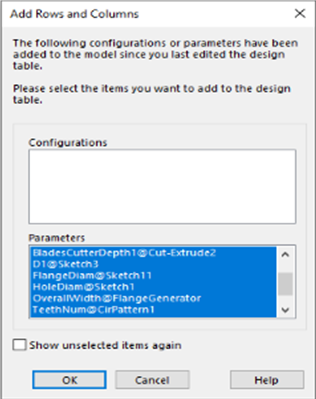

Solution: Setting Up Design Tables

Design Tables automate configuration management and mass tracking. Here’s how to set them up:

Steps to Set Up Design Tables and $SW-MASS

Figure 2: Initial Design Table Setup with 3D Pulley Model

Figure 3: SOLIDWORKS Configuration List

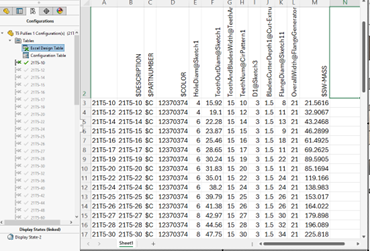

Figure 4: Excel Design Table with $SW-MASS Data

Linking Custom Properties in Design Tables

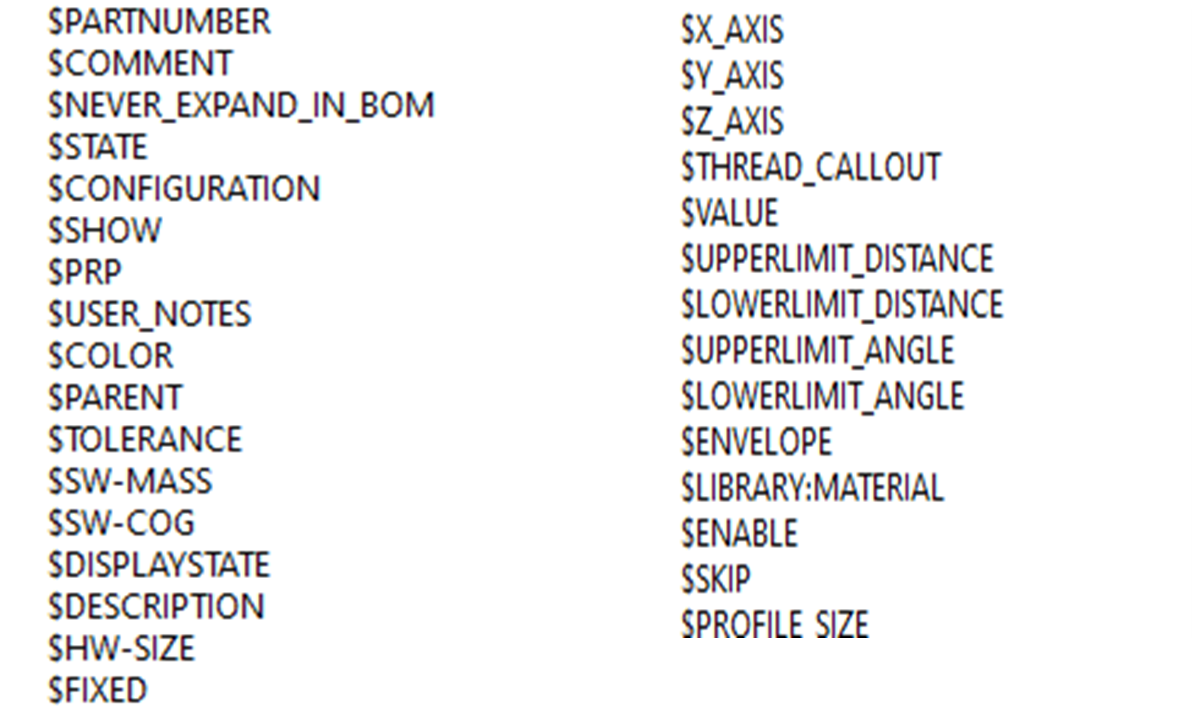

SOLIDWORKS allows linking additional custom properties to Design Tables for comprehensive data management. Examples include :

Figure 5: CUSTOM PROPERTY

How to Link:

Benefits of Using Design Tables and Custom Properties

Conclusion

Setting up Design Tables with $SW-MASS and custom properties automates configuration management and data tracking, ensuring accuracy and efficiency in parametric designs. This approach is ideal for parts like pulleys with multiple configurations. Experiment with your models to leverage these tools effectively.

Engineering Technique is an Authorized Value-added Reseller of SOLIDWORKS Desktop 3D CAD & 3DEXPERIENCE Works Cloud CAD software in Ahmedabad, Vadodara, Surat, and across Gujarat, including Mumbai.

For inquiries, feel free to reach out:

Call: +91 94276 11239

Email: marketing@enggtechnique.com

Thank you for Reading!

Author: Chirag Patni, Post Sales Application Engineer