In today’s fast-paced product development landscape, time is not just money—it’s competitive advantage. Engineers and analysts are under constant pressure to deliver high-fidelity simulations faster than ever, without compromising accuracy or innovation. Traditional on-premises computing resources often fall short when handling large, complex simulation models, leading to extended run times and bottlenecks in the design process.

This is where High-Performance Cloud Computing (HPC) on the SIMULIA 3DEXPERIENCE platform comes into play. By harnessing the power of scalable, on-demand computing in the cloud, teams can dramatically accelerate simulation workflows, improve productivity, and make critical design decisions earlier in the development cycle. In this blog, we’ll explore how HPC on 3DEXPERIENCE transforms simulation performance and why it’s a game-changer for modern engineering.

One of the most underrated yet transformative advantages of running simulations on the cloud through the SIMULIA 3DEXPERIENCE platform is the freedom it gives your local resources—and yourself.

Traditionally, long simulation runs meant leaving your workstation on for hours, sometimes overnight or even across entire weekends. Not only does this tie up your local system, but it also creates risk—power cuts, system sleep, overheating, or unexpected crashes can interrupt the process, wasting precious time.

With cloud-based HPC, your simulation runs on powerful, secure remote servers, not on your local machine. Once submitted, it processes independently in the cloud, while you’re free to turn off your laptop, close your office, or shift your focus to other tasks. The results are automatically saved and accessible from anywhere, anytime, within your 3DEXPERIENCE environment.

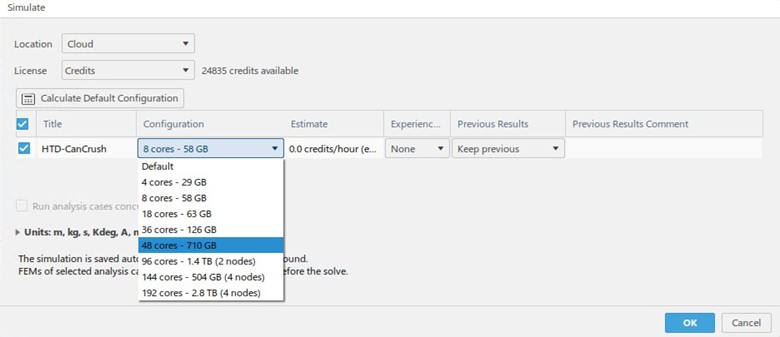

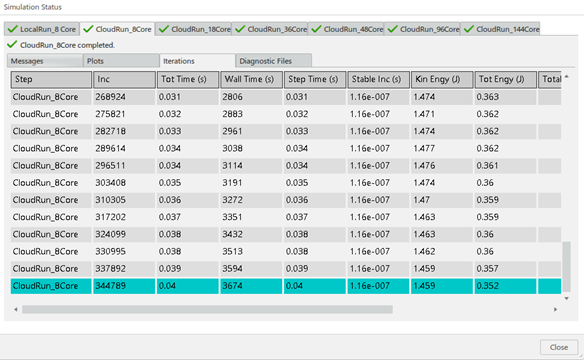

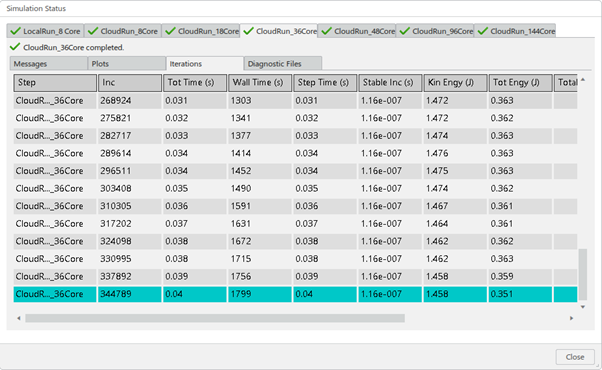

To truly showcase the power of cloud-based HPC on the SIMULIA 3DEXPERIENCE platform, we ran a classic can crush simulation across various core configurations—from a standard 8-core local machine to a 144-core cloud environment.

The difference was striking.

Running locally on 8 cores, the simulation took a significant amount of time, limiting iteration speed and slowing down design decisions. However, as we scaled up cloud resources—moving from 16 to 36, then 72, and finally 144 cores—we saw reductions in run time at every stage.

Fig.1 HPC Cloud Core

Fig.2 Cloud 8 Cores – Simulation Time (Seconds)

Fig.3 Cloud 36 Cores – Simulation Time (Seconds)

| Core Count | Environment | Simulation Time | Speed Up |

| 8 Cores | Local | 62 min | 1 |

| 8 Cores | Cloud | 61 min | 1.02 |

| 18 Cores | Cloud | 40 min | 1.55 |

| 36 Cores | Cloud | 29 min | 2.14 |

| 48 Cores | Cloud | 28 min | 2.21 |

| 96 Cores | Cloud | 28.5 min | 2.18 |

| 144 Cores | Cloud | 35 min | 1.77 |

Table.1: Core & Simulation Speed up Comparison

Above table also showcase it maximum time reduction can be done up to 30 to 35 minutes for current example of “can crush”, reason is not all work done in simulation is in parallel but there are some dependencies in solving the problem, apart from that as you add more cores, the system spend more time in coordinating the task between them. More threads mean more overhead in synchronization, communication and data sharing. If the task isn’t truly parallel and have dependencies some cores will just sit idle wating.

If reducing simulation time remains a priority even after optimizing core counts, mass scaling becomes a valuable technique worth exploring.

Mass scaling works by artificially increasing the mass of elements in a simulation to allow for a larger stable time step, ultimately reducing the number of iterations needed. The effectiveness of mass scaling depends on several key factors:

By adjusting any of these parameters, users can potentially achieve faster simulation times. However, mass scaling must be applied with caution. While it can significantly improve performance, improper usage may affect the accuracy and stability of the simulation.

When applying mass scaling, it's essential to monitor the following energy components to ensure realistic and reliable results:

Mass scaling is a powerful tool, but it's not a silver bullet. It requires careful balancing between performance gains and physical accuracy. This topic opens the door to a deeper discussion, which we’ll explore in a future blog post — including best practices, use cases, and how to apply it safely in your simulation workflows.

Engineering Technique is an Authorized Value-added Reseller of SOLIDWORKS Desktop 3D CAD & 3DEXPERIENCE Works Cloud CAD software in Ahmedabad, Vadodara, Surat, and across Gujarat, including Mumbai.

For inquiries, feel free to reach out:

Call: +91 94276 11239

Email: marketing@enggtechnique.com

Thank you for Reading!

Author: Pranav Shukla, Sr. Simulation – (CAE)