The Packaging Machinery Industry has evolved considerably over the years. Stipulated standards now pose for increased environmental concerns and the need for globalisation. Companies utilizing packaging machinery need to constantly anticipate the volatile demands of their customers regularly.

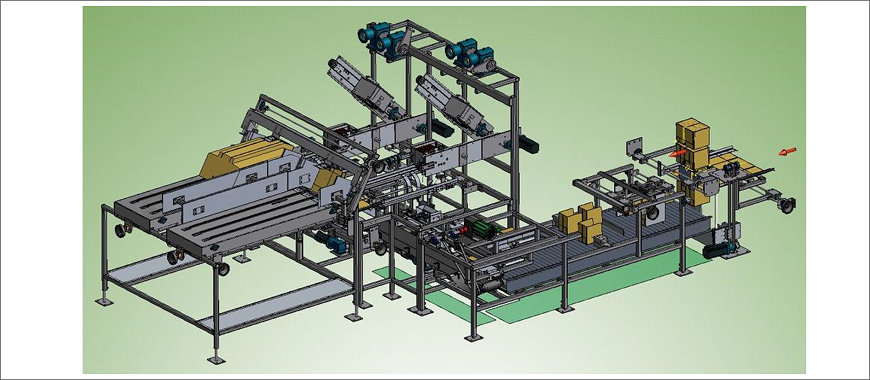

The challenging packaging machine design operations require manufacturers to be aligned with current trends and automate the processes. They are in dire need of an upgrade from operational methods, evolving from non-integrated solutions to fully-integrated approaches for 3D design and manufacturing. Automation ensures these companies a faster time to market and a marked rise in quality too.

SOLIDWORKS and its expansive range of product development solutions can enhance and boost efficiency of production by several notches. The solutions help reduce time, effort, and costs related to manufacturing and operations, while enriching the packaging industry’s performance, flexibility, reliability, and safety.

1. Boosts Competitiveness and Controls Costs

An integrated ecosystem like that of SOLIDWORKS can deliver concurrent workflows, along with data compatibility. The system leverages 3D design data within all package machinery functions boosting efficiency, reducing costs, and enhancing quality. Some of the popular products under the SOLIDWORKS canopy includes SOLIDWORKS 3D CAD and SOLIDWORKS PDM.

2. Get a streamlined 3D Ecosystem for Manufacturing Packaging Goods

SOLIDWORKS ensures a streamlined 3D Design-to-Manufacturing ecosystem that integrates all levels of mechanical and electronic design in line with the electrical schematics. The system also engages and ensures an ideal end product with comprehensive simulation and product data management. The system also adheres to a model-based definition providing constant inspection on the processes with definite visualization attributes that are handy to success. Some of the products under the SOLIDWORKS canopy include SOLIDWORKS Electrical 3D, SOLIDWORKS MBD, and SOLIDWORKS Inspection.

3. Boost Profitability with Integrated Solutions for 3D Design

Packaging machinery companies are forever facing the volatile economic and commercial business climate to which they need to respond in a jiffy to be relevant for the present as well as the future. These organizations understand that they need to respond to competitive forces without delay, or else their future success is in jeopardy. SOLIDWORKS integrated 3D solutions helps these companies save on ample time, money, and effort, while ramping up quality measures along with widespread innovation. Some of the highlighted products in its canopy that ensures boost in profitability include SOLIDWORKS Visualize and SOLIDWORKS Manage.

Packaging machinery design is a complex process in itself and the competition today necessitates innovation in the sphere. Additionally, companies are keen to get to the market faster than any of their peers or competitors.

SOLIDWORKS software can help these companies meet these seemingly tall challenges, enabling them to explore and test varied design options, boost quality, and streamline their processes.

• SOLIDWORKS 3D CAD

This software provides powerful functionality that reduces product development time and costs, while enhancing quality. The packages encapsulate 3D design, cost estimation, overall simulation, checks on manufacturability, sustainability in design, and efficient data management.

• SOLIDWORKS PDM

This software takes care of Product Data Management (PDM), essential for managing data files efficiently to maximize productivity. It securely stores and indexes all design data files, ensuring swift retrieval, without the risk of data loss, and ensure seamless collaboration on designs with remote teams in multiple locations.

• SOLIDWORKS eDrawings

This software helps engineers to develop 2D technical drawings derived from the 3D CAD model, aligned with the latest features. It also ensures safe storage and accessibility of data. The drawings can be saved to PDFs to SOLIDWORKS Composer files that list out assembly instructions alongside the eDrawings for an easy understanding to systems without the software been installed. One could create photorealistic renders of image formats to share among non-CAD users for concept communication.

• SOLIDWORKS Simulation

This software integrates into the modelling area for preparing analysis to be run during the modelling process. It assesses the design in the context of real-life scenarios. SOLIDWORKS Simulation can run analysis and tests on several settings and scenarios, from buckling analysis to nonlinear stress analysis.

• SOLIDWORKS Composer

SOLIDWORKS Composer can convey ideas through diverse formats, inclusive of 2D technical drawings to SOLIDWORKS Composer files that can specify assembly instructions near the eDrawings. The 3D tool repurposes all kinds of 3D engineering data to explain routine processes and procedures in the industry through communications. This software helps in developing assembly instructions, product utility manual, installation instructions, service manuals, brochures, and sales kits effectively.

• SOLIDWORKS Inspection

This software automates the ballooning of drawings and 3D files with PMI, reducing time required to record inspection measurements and streamlining the development of inspection reports as per industry standards.

• SOLIDWORKS Plastics

This software ensures quick and efficient simulation for plastic parts analysis along with performance of injection molds. It simulates plastic flows with the help of injection molding process to ascertain flaws in the workflows and points out manufacturing-related defects, if any. This correction helps professionals to evaluate part manufacturability in a swift manner while designers continue to design.

Companies in the packaging sector can benefit immensely in present times with a streamlined, automated approach guaranteed by SOLIDWORKS platform for packaging machinery design.

Engineering Technique is an Authorized Value-added Reseller of SOLIDWORKS Desktop 3D CAD & 3DEXPERIENCE Works Cloud CAD software in Ahmedabad, Vadodara, Surat, and all over Gujarat.

For Inquiry: Call on +91 94276 11239 | Email: marketing@enggtechnique.com