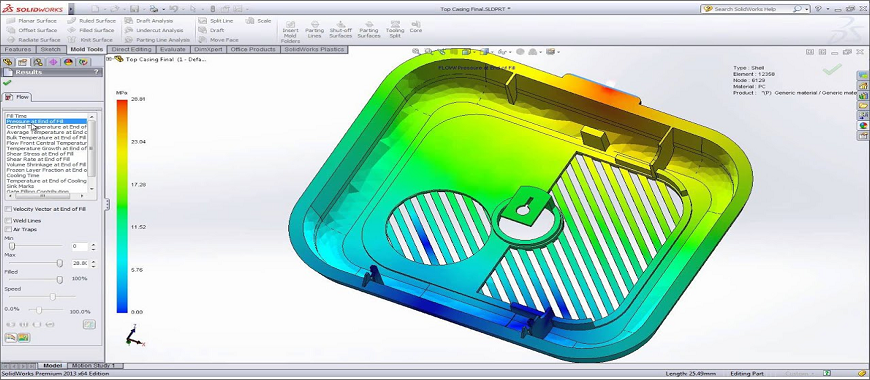

SOLIDWORKS® Plastics delivers easy-to-use simulation for analyzing plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects so you can quickly evaluate part manufacturability while you design.

Watch this webinar recording to Learn the Best Practices of Injection Molded Plastics Part Design.

Here’s Summary:

• Injection Molding Overview

• The key factors to keep in mind to determine the best polymer material candidates for your application

• Common defects in injection molded parts

• The best practices for optimizing your part designs for the injection molding manufacturing process

Engineering Technique is a SOLIDWORKS Authorized Reseller in Gujarat providing comprehensive solutions for SOLIDWORKS Software products including 3D CAD, Product Data Management (PDM), Plastics Simulation, Visualize, eDrawings, and DraftSight to industrial verticals including Industrial Equipment, Consumer Goods, Life Sciences, Manufacturing, Alternative Energy, Process & Plant, etc. Their clientele spans 600+ customers in design and manufacturing domains with 1850+ licenses in the state of Gujarat itself.

Read also:

• How SOLIDWORKS Plastics Enhances Manufacturing Design and its Quality

• SOLIDWORKS Plastics: Perform a Simulation to Analyze Injection Moulds and Plastic Parts