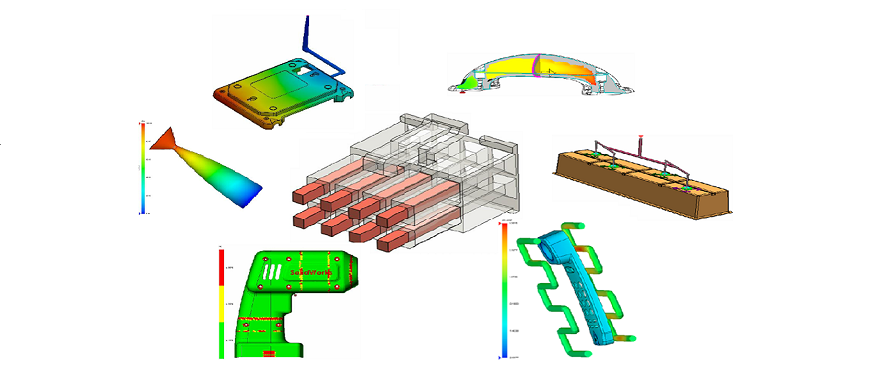

SOLIDWORKS Plastics ensures the efficient simulation of easy-to-use injection molding to design engineers, thus helping them predict any defects in the manufacturing framework of intended molds and parts. One can leverage SOLIDWORKS Plastics for design, enhance part quality, and boost the required time to market, thus reducing chances of mold rework that would mean loss of time, effort, and money. The simulation tool can be used to provide technical insights to design engineers for further innovation to the parts, making them more efficient and flawless.

Designers can enjoy accurate designs and develop optimal injection molds that could include runners, gates, and spruces. The structure can help designers gauge cycle time and balance runner systems and set tonnage efficiently.

SOLIDWORKS Plastics can easily optimize thickness, gate locations, and runner size along with the layout of the plastic products based on the efficient performance of the molds, made right the first time around.

SOLIDWORKS Plastics ensures proper analysis of design iterations based on product development efficiency, impacting manufacturability with high part quality and minimal scrap production rates.

The simulation tool predicts manufacturing defects based on mold performance before leading to wide-scale manufacturing, eliminating the need for costly mold rework and thus ensuring that deliverables are met within deadlines and budget.

SOLIDWORKS Plastics helps in preparing automated reports for sharing and analysis of simulation results, facilitating prompt collaboration among stakeholders and other teams.

This package presents plastics part designers with injection molding simulation related to the flow of melted plastic during the molding process. This process helps designers to predict the faults and defects related to the manufacturing of parts and molds, before the actual process. A swift evaluation of the part’s manufacturability helps designers avoid costly mold rework, and thus enhance the efficiency of the parts as well as its quality.

Plastics part designers can use the professional version of the simulation tool to optimize parts for wide-scale manufacturing right in the early design stages. This version is embedded within the CAD environment for prompt analysis of parts for design modifications, helping them to be optimized based on structure, size, fit, and function.

The Premium version provides designers who build injection molds, a perfect tool to optimize their utility. They can swiftly develop and analyze mold layouts, including runners and gates. The tool helps the users to estimate cycle time along with the shot size and clamp tonnage, for an efficient end design for the wide-scale manufacturing of parts.

Partner with Engineering Technique today! Rest assured; their competent SOLIDWORKS Plastics Engineers have your needs covered.

Engineering Technique is a SOLIDWORKS Authorized Reseller in Gujarat providing comprehensive solutions for SOLIDWORKS Software products including 3D CAD, Product Data Management (PDM), Simulation, Visualize, eDrawings, and DraftSight to industrial verticals including Industrial Equipment, Consumer Goods, Life Sciences, Manufacturing, Alternative Energy, Process & Plant, etc. Their clientele spans 450+ customers in design and manufacturing domains with 1850+ licenses in the state of Gujarat itself.