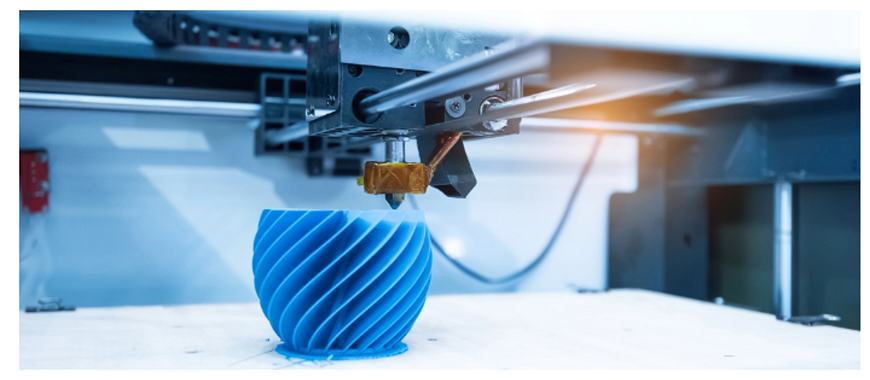

In recent years, 3D printing services have demanded a huge interest in various applications. The platform technologies of 3D printing have evolved in recent times, even becoming inexpensive enough for hobbyists and small businesses to develop a host of models and products.

Now companies are creating affordable items with everything ranging from low-quality plastics to metals. The devices are expected to help the manufacturing industry evolve or just be ancillary tools like knitting needles that are powerful in some hands, and not for everyone else. Only time will tell.

Experts presume that 3D printing services could facilitate a strong approach to mass customization while exploring diverse revenue streams and even extend support for extraneous parts that are required by large-scale machinery that are bought at low volumes.

The possibilities outlay the opportunities 3D printing may introduce, and feed into how technology can be used to help companies build large-scale relationships.

It is evident that 3D printing technology has broad business implications with cost savings especially in areas of product development, testing, packaging, and logistics.

Based on recent developments, 3D printing pushes for bright business prospects for many industries, including automotive, electronics, and industrial products. The real innovations are based on how 3D printing can commence on new business opportunities.

3D printers are capable of addressing the inherent problems of mass production especially in producing objects with tweaks in tools with a wide range of customizations on diverse objects.

Related article: DAMBOY – A 3D Printer which is Made in India

The 3D printers are also handy in mass customization of products that are released with similar parameters, especially golf club grips, a drawer handle, or shirt sleeves for that matter. The small tweaks required to meet other people’s requirements could be performed through tweaks in parameters set through 3D printers. They could print items within hours in a specific space or a specialized offsite facility wherein other materials are also used simultaneously. In such cases, putting in just the design parameters would not work well. Designers must also decide the attributes that can be open to flexible parameters along with limits that can be imposed on them. The revenue streams that open to customization could also lead to a longer shelf life for the said product.

3D printers can also lead the pack of manufacturing companies who are concerned about on-demand production without bulk demand. Several objects especially electrical appliances that are used in daily lives are damaged with the absence or failure of a single part. Refrigerators cannot work when the doors break down or the microwave oven would not work without the buttons working. With 3D printers, these parts could exist in a catalog virtually, that could be realized on demand when the need arises. The ordered parts could be dispatched directly to the customers without hassles. Industrial equipment and additive manufacturing vendors now could utilize a 3D printer to produce objects that are required onsite instead of dispatching varied metal replacement parts that have had to be mass-produced.

Several marketplaces have cropped up that encourage low-volume products for all kinds of buyers. 3D printing will evolve and become economical enough to develop products at low volumes and reasonable prices with mass customization. The distribution costs could drop down significantly in this regard.

Customers will have more control over the products that they need just as they can digital goods are putting control back into the hands of the consumers. Organizations would have to identify the right products to print and fulfil requests. In terms of product development, businesses will have to opt for sustainable practices that would involve design and part replacements, and even in designing specific component replacements. This opens up wider revenue streams that could lead to 3D printing companies to forge partnerships with retail chains for 3D printing and repair services that will also lead to lower machine waste in the long run.

Related article: DAMBOY – The Most Affordable and Accurate FDM 3D Printer

Engineering Technique delivers DAMboy, the most affordable FDM technology-based 3D Printer that is known for its accuracy and precision in 3D parts in its segment. We deliver DAMboy FDM 3D Printers to High schools and engineering students so that they leverage 3D Printed models for their education. The 3D printer is also used for meeting prototyping needs of various industries, i.e., Manufacturing, Consumer Goods, Product Design, Toys & Miniature, Architecture, and others.

The company also offers EnvisionTEC’s professional-grade 3D printing solutions that help build precise, functional objects for prototypes and tooling purposes. These 3D printers serve medical, professional and industrial markets, providing much vaunted functionality and speed.