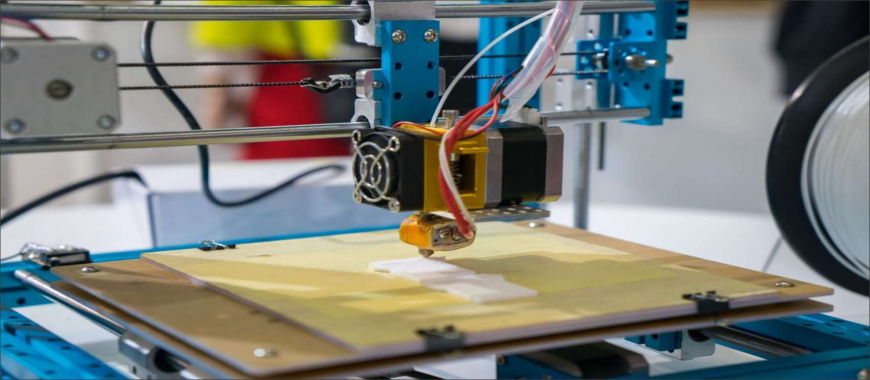

The number of applications that depend on 3D printing in the consumer goods industry increased. A whopping 76% of firms have already adopted 3D printing technologies. This rise has opened up new avenues for designing and developing prototypes, tools, and parts production. Eventually, the technology is expected to evolve and benefit varied domains in unexplored ways.

3D printing allows designers to create high-quality aluminum molds with complex textures which are unmatched by traditional designing techniques. For example, shoe molds.

Complex 3D printing technologies assist designers in speeding up prototype creation with the injected blow mould parts. Hundreds of parts can be created simultaneously, thus, reducing costs. Hence, the products witness a quicker launch.

3D printing allows for the customization of products and designs. What’s more, it is inexpensive. The only tools required for manufacturing a product is within the machine. Once the design data is transferred to the printer, it is printed quickly.

Unlike traditional manufacturing techniques, 3D printing is much quicker. For example, 3D printing assisted a packaging company in reducing months’ worth of development time to days. Before 3D printing, Computer Numerical Control (CNC) techniques was quite popular for the same purposes. Designing a prototype with CNC would take a few weeks.

3D printing has revolutionized the consumer goods industry by accelerating design evaluation concepts. These services allow prototypes to be created and altered overnight, if necessary. Multi-material 3D printing, which enables the designing of prototypes with a combination of colours and textures, is picking up pace. This fact helps render the new creations with the feel of a final product.

3D printing allows designers to create complex and seemingly impossible designs as per traditional standards. For example, shoe soles with embedded lattice structures are optimized for ultimate durability and strength.

3D printing services focus on additive manufacturing instead of traditional manufacturing practices, reducing waste and supporting sustainability measures.

With 3D printing, one can create tools and injection moulds consistently. 3D printing services enables companies to build machine parts in a short time frame at a reduced cost. Around 39% of companies in the consumer goods industry find it viable to create tools with 3D printing services. For example, Unilever uses 3D printing for creating prototypes for testing purposes. Effectively, they cut down lead times by 40%.

The consumer goods industry continues to explore possibilities with 3D printing and addressing gaps in demand through innovation and thorough feasibility analysis. One can expect several new products and unique processes in the domain, in the near future.

Related article: